Высокая температура | Решения Mengneng Покрытия

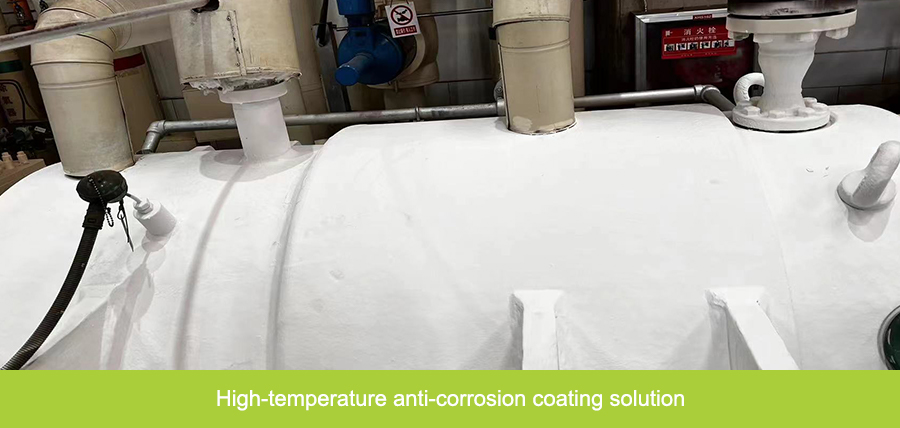

With the development of industries such as aerospace, energy, chemical, metallurgy, power, and machinery, the performance requirements for materials have become increasingly higher. Some equipment and pipelines experience corrosion due to the presence of corrosive media, especially high-temperature equipment. These include the inner and outer walls of blast furnaces, hot blast stoves, chimneys, flues, drying channels, exhaust pipes, high-temperature gas pipelines, heating furnaces, heat exchangers, and other high-temperature equipment made of both metallic and non-metallic materials. Under the influence of high temperatures and corrosive media, rapid corrosion can occur.

-

Фон коррозии

Фон коррозии -

Проектные нормы

Проектные нормы -

Обычные аксессуары

Обычные аксессуары -

Реакторы давления

Реакторы давления -

Стальные дымовые трубы

Стальные дымовые трубы -

Ротационные печи

Ротационные печи

-

- Фон коррозии

-

I. Corrosion Background

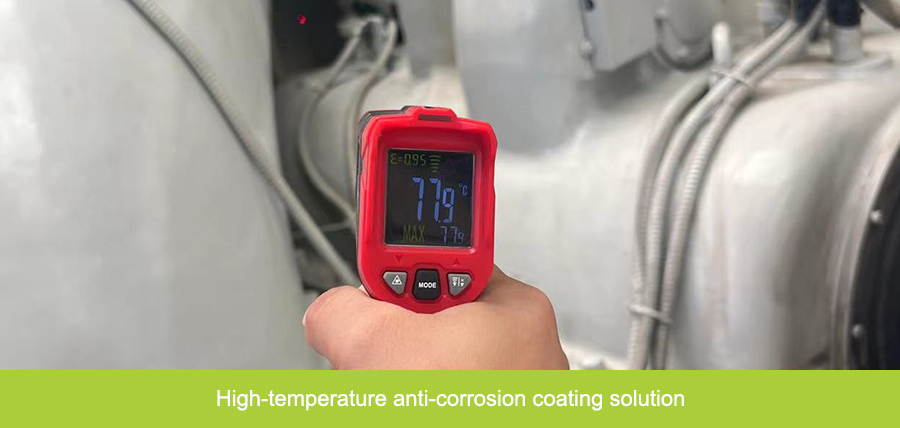

Currently, severe corrosion issues are common in industries such as chemicals, metallurgy, and power generation. Extensive work has been done on normal temperature corrosion, and significant progress has been made. However, for high-temperature (above 400℃) corrosion environments, such as cement kiln exhaust gas dust collectors, high-temperature and high-pressure reactors in petrochemical plants, and boilers in thermal power plants, most equipment operates in sulfur-containing and corrosive gases at around 600℃. Mengneng Technology’s corrosion protection experts point out that under these harsh conditions, the lifespan of metal equipment is reduced, production costs increase, and significant safety hazards arise. For example, a company producing sulfur dioxide roasting furnaces with high-temperature resistance, where the metal temperature can reach 600℃, faces severe corrosion of the metal due to the abundance of corrosive gases and high friction. Without good corrosion-resistant materials for protection, a 40mm thick metal plate in the furnace was corroded through in just three months. Also, some chemical production furnaces reach temperatures up to 1200℃, and under high-temperature corrosion from highly corrosive gases, the furnace materials rapidly corrode, leading to production interruption and significant resource waste.

-

Просмотр в деталях

We don't know where to start.

-

Миниатюрный просмотр

Как выбрать правильный тип покрытия?

-

ISO 12944 — это стандарт для защиты от коррозии стальных конструкций с помощью красок, который определяет коррозионную среду, срок службы антикоррозийного покрытия, соответствие краски и толщину пленки.

Corrosion factors are numerous and varied.

-

Выбор

Как решить проблемы отрасли с помощью покрытий?